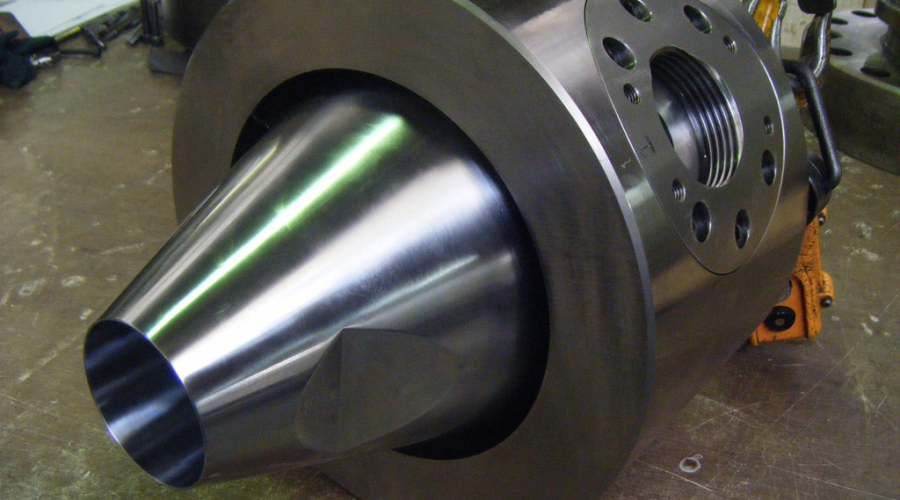

At Absolute Tooling we can repair, re-engineer, or rebuild a wide range of industrial equipment. This is especially useful when parts are difficult to source, out of production, or very expensive to buy from OEM suppliers overseas.

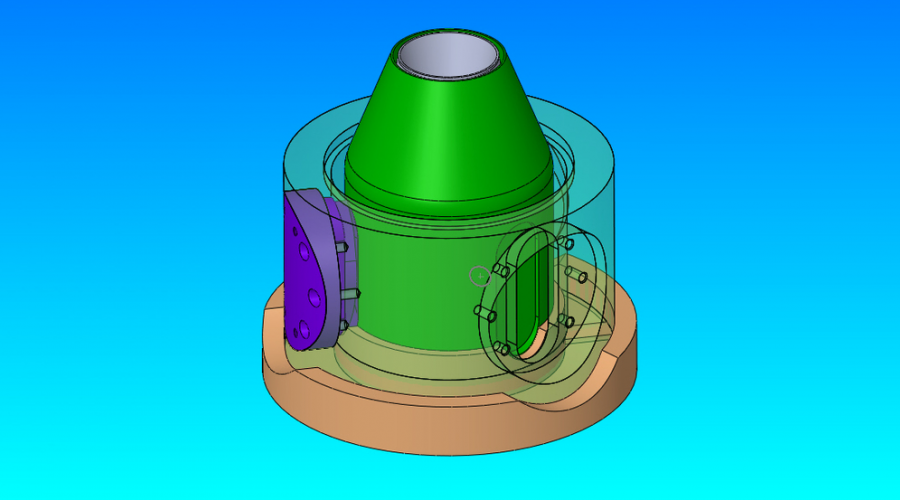

We can model, prototype and manufacture replacement parts quickly and efficiently.

We can remanufacture old components which are difficult to source, or we can remanufacture expensive OEM parts at cost effective prices, even for small quantities.

Replacement parts can be made from steel, tooling steels, alloys, engineering plastics, or 3D Printed in-house.

Our responsiveness makes us a key business partner for many industrial businesses in the Manawatu and Central North Island.

Our expertise includes the following areas:

- Maintenance and repairs of hydraulic and pneumatic equipment

- Machining, welding and resealing of hydraulic valves

- Repairs to gears, vanes, pistons, replacement spears, motors and gearboxes

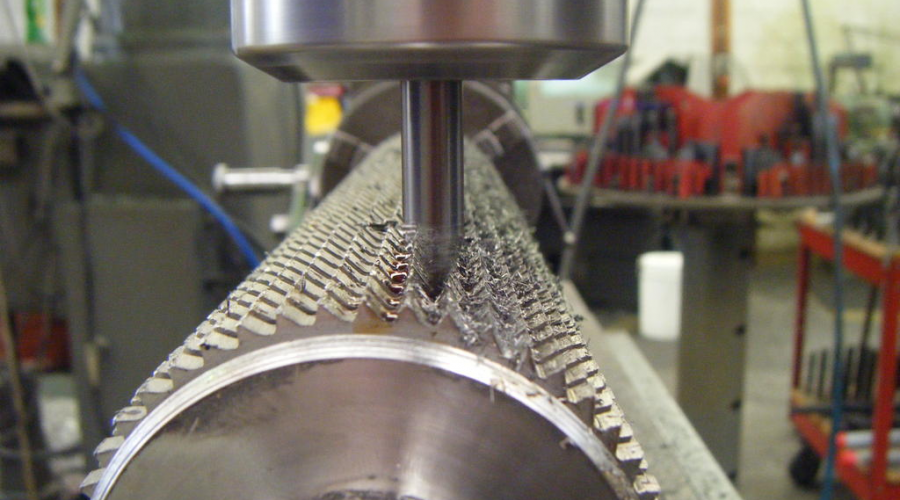

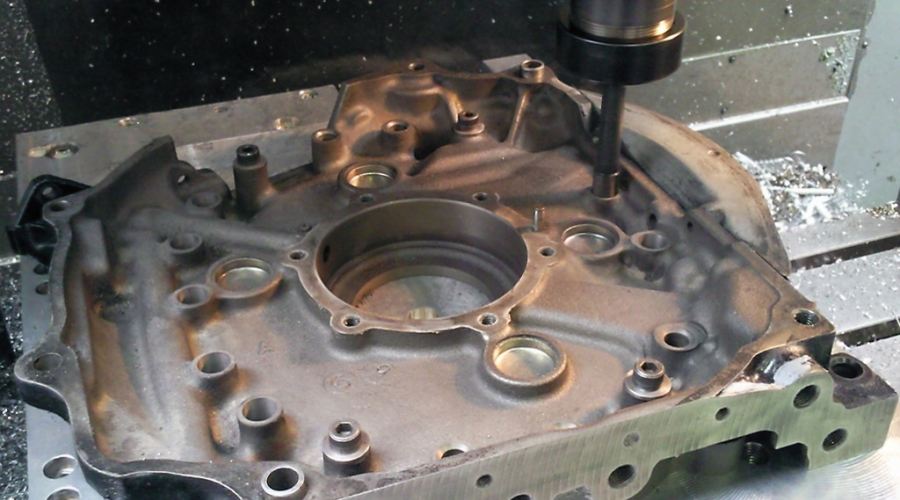

- CNC machining and turning

- Surface grinding

- Resurfacing or build up of shafts or housings for turning or re-machining

- Milling and boring

- Honing and lapping

- Chasing and repairing threads, nuts and tapped fittings

- Spark erosion to remove broken drills, bits, taps, and studs from within housings without damage

No job is too big or too small - whether it's a small welding job for home or a large industrial plant overall.