Precision Machining

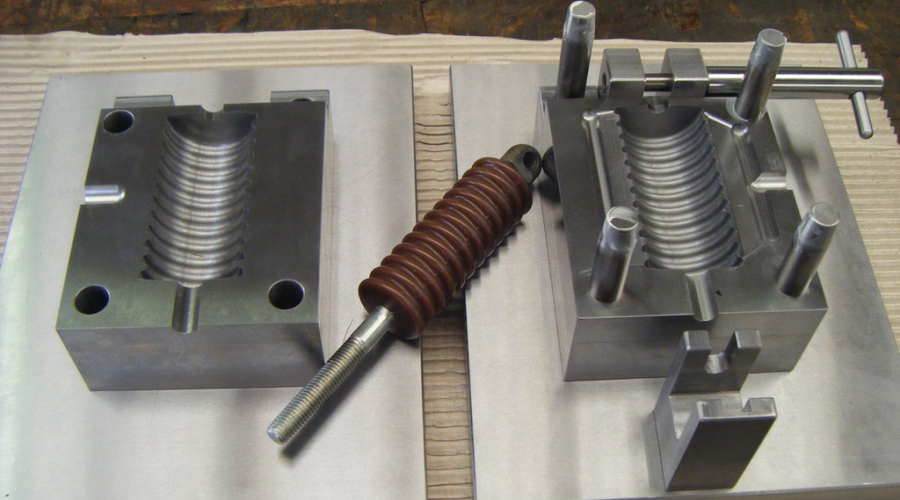

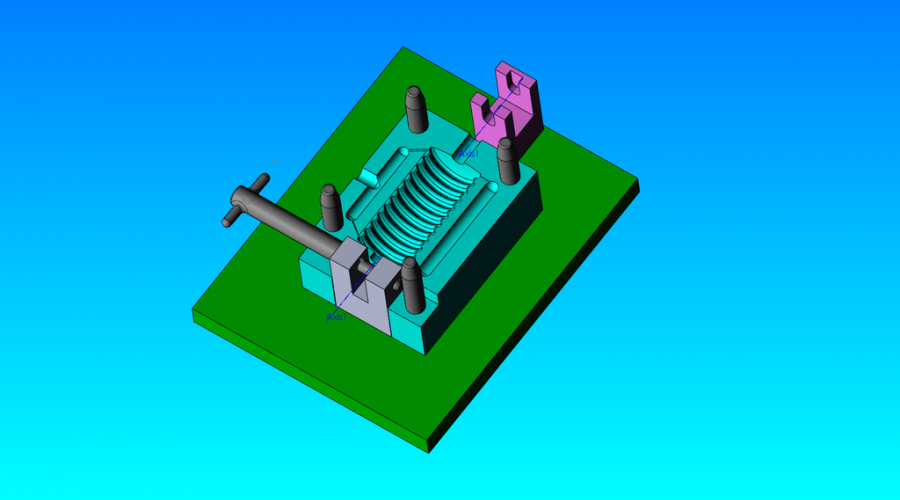

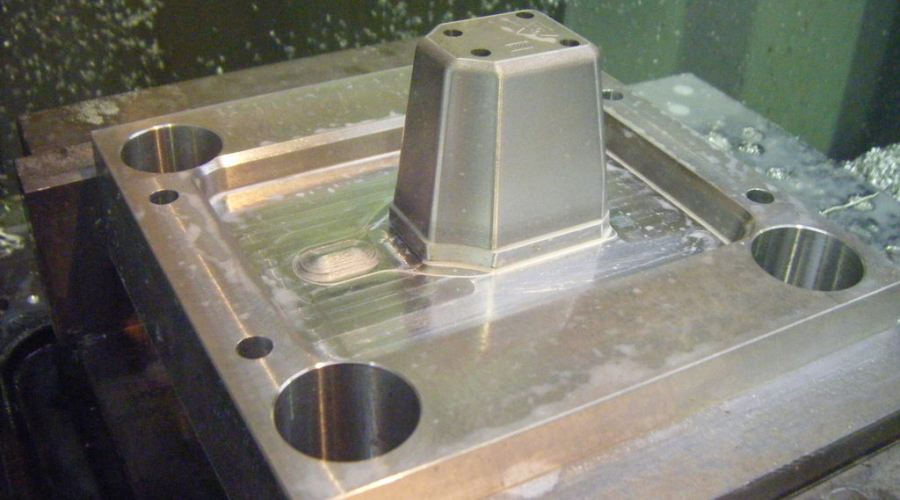

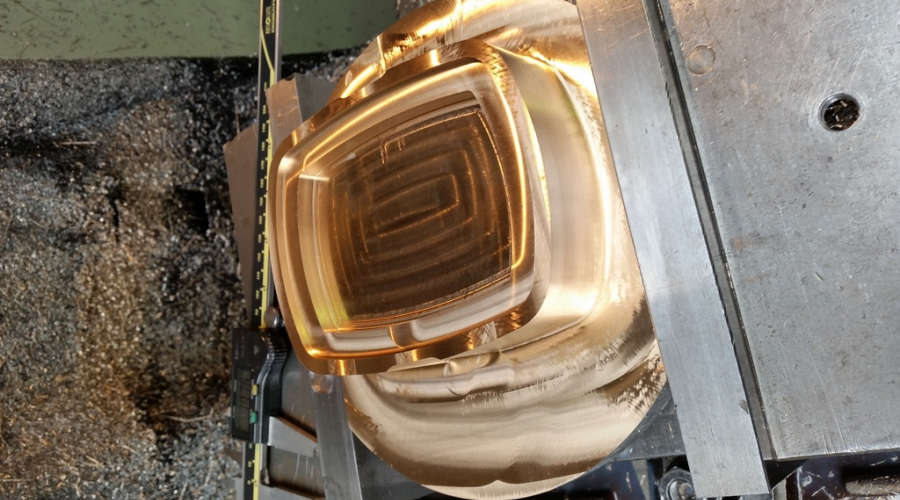

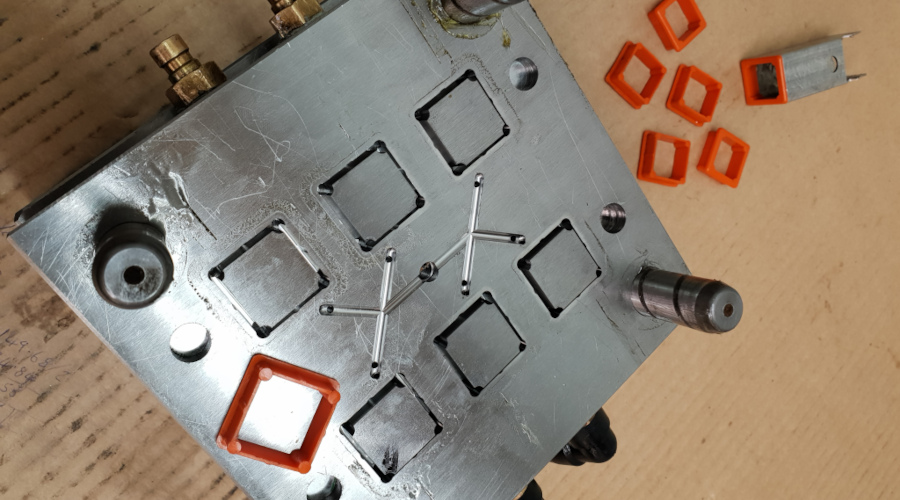

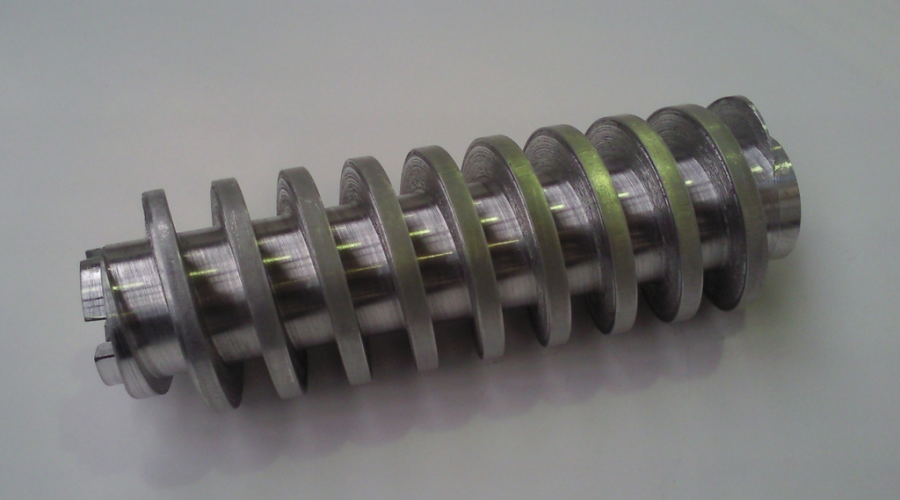

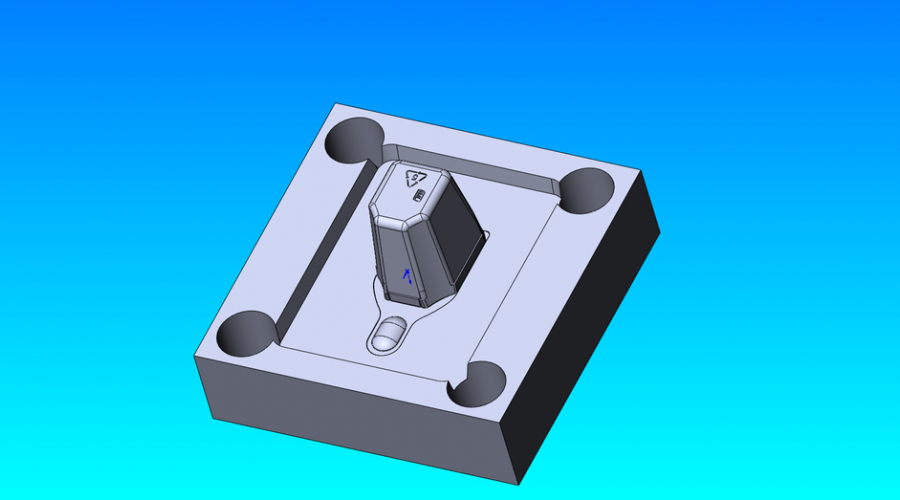

Precision machining is what we do. We can design and machine to very fine tolerances using precision CNC lathes, CNC machining centres, spark erosion (EDM), surface grinding and cylindrical grinding.

We work with all types of steels, specialist tooling steels and engineering plastics, as required for your needs.

Common precision work for us includes refurbishment of high speed spindles, repair of shafts, rollers, food machinery, pneumatic and hydraulic systems, machinery improvements and repairs, pins and bushes, sharpening and re-setting of industrial blades, and surface grinding of industrial components.

ATS offers machine shop services for repairs and maintenance of pneumatic and hydraulic equipment. We can repair and machine old cylinders. Machining, welding and resealing of hydraulic valves. We can repair gears, vanes, pistons, replacement spears, motors and gearboxes. Service and maintenance of hydraulic systems. Chasing and repairing threads, nuts and tapped fittings.

We will also rebuild and service production machinery.

-900x500.png)