Our knowledge and experience of the process and what is involved in creating a new product can bring your idea to life. We'll help you solve problems and develop up new ideas with the help of our expert team. We're a "one stop shop" for product development which ensures confidentiality, quality and value for money. Frequently Asked QuestionsQ1: Can you help me design my product?

A1: Yes. Absolute Tooling have expertise in both product design and tooling. The product design process starts with market research and an initial review for overall project viability. We aim to gain an understanding early in the project of likely costs, sales volumes and pricing. We will also review relevant Intellectual Property which may impact on design requirements. We will work closely with our client to develop up concepts that meet both the engineering needs and aesthetic requirements of the product, for a first rate result. Once designs are under-way, Absolute Tooling can quickly 3D print physical models in-house to assist in the product design process. In-house 3D printing can save a tremendous amount of time during the product refinement process. This enables better solutions, faster. Q2: Is my idea safe?

A2: Yes. Our reputation is based on keeping your data safe. We will ensure appropriate non-disclosure agreements are used. Q3: How long will it take?

A3: From a few days to 3 months depending on complexity. Click here to contact us for an estimate. Q4: How much?

A4: From $90 to $150,000. Click here to contact us for an estimate or to discuss your needs Q5: Do you have examples?

A5: Yes. Click here to view our Portfolio of past products and projects. Q6: Why Choose Absolute Tooling?

A6: You can save yourself a lot of time and money by using a tooling firm. Not only do we know industrial design and product design, but we know toolmaking. It’s much more efficient to be able to do it all in one place. Features and Benefits- Confidentiality is paramount. We ensure your idea is kept safe by supplying confidentiality agreements and secure premises and processes

- We have the experience to guide you through the entire process from concept to finished product

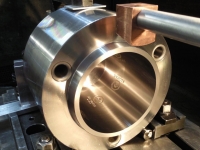

- Our toolmaking, mould making, blow moulding, die casting and plastic injection moulding create the ability to manufacture precision parts economically saving you money and time

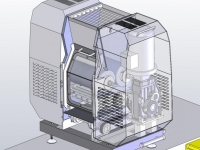

- Our CAD modelling service allows you to visualize your idea in 3D

- We can provide in-house 3D Printing so you can physically see, test and market your idea

- We can provide CNC machining to precisely machine components to exacting specifications

- We can use Spark erosion when machining challenging pieces with intricate detail

Email or call for a free quote |